Hamza Asumah, MD, MBA

Lean management is a set of principles and practices that aim to increase productivity, reduce waste, and improve efficiency in organizations. Lean management practices can be useful in healthcare businesses in Africa, where resources are often limited and there is a need to maximize efficiency.

Photo By Simplilearn

There is a growing body of evidence that suggests that implementing lean management systems can help improve productivity and reduce waste in healthcare businesses. Here are a few examples of studies that have examined the impact of lean management on healthcare business productivity and waste reduction:

1. A study published in the International Journal of Health Care Quality Assurance examined the impact of implementing lean management in a hospital in the United Kingdom. The study found that implementing lean management led to a 30% reduction in patient waiting times, a 50% reduction in medication errors, and a 20% increase in employee productivity.

2. A study published in the Journal of Healthcare Management examined the impact of lean management on a hospital in the United States. The study found that implementing lean management led to a 19% reduction in patient waiting times, a 20% increase in patient satisfaction, and a 16% increase in employee productivity.

3. A study published in the Journal of Hospital Medicine examined the impact of lean management on a hospital in Canada. The study found that implementing lean management led to a 50% reduction in patient waiting times, a 20% reduction in the length of hospital stays, and a 30% reduction in the number of medication errors.

4. A study published in the International Journal of Healthcare Management examined the impact of lean management on a hospital in South Africa. The study found that implementing lean management led to a 40% reduction in patient waiting times, a 20% reduction in the length of hospital stays, and a 15% increase in employee productivity.

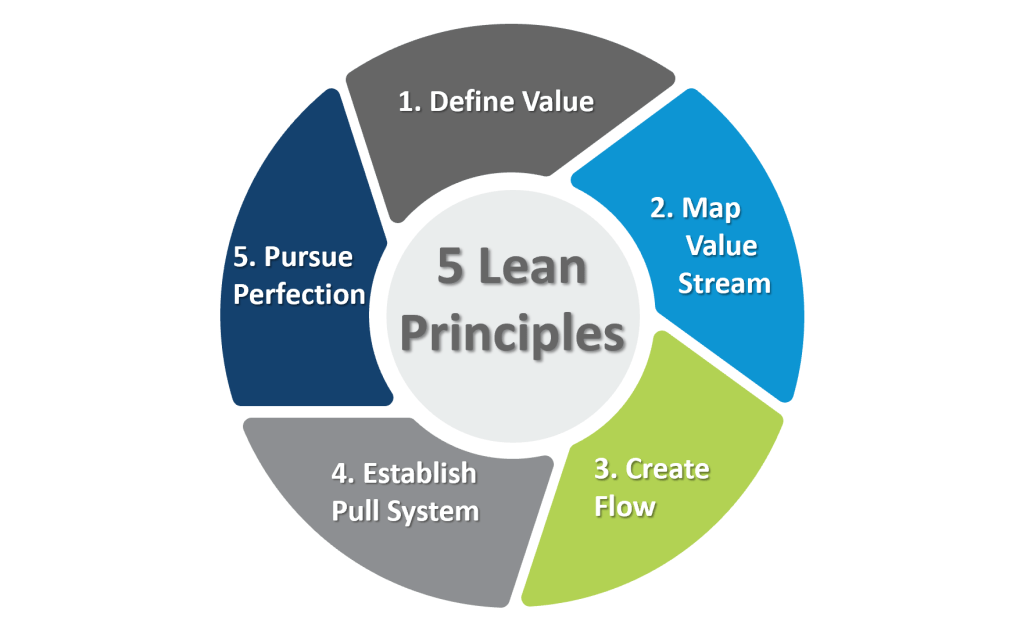

Photo By Planet Together

Here are some of the key principles of lean management:

1. Value: Lean management starts by focusing on the value that the customer receives from a product or service. Value is anything that the customer is willing to pay for.

2. Value Stream: A value stream is the sequence of steps that are required to create a product or service. Lean management seeks to identify and eliminate any steps in the value stream that do not add value.

3. Flow: Once the value stream has been optimized, it is important to ensure that the process flows smoothly. Lean management seeks to eliminate bottlenecks and other obstacles that can slow down the process.

4. Pull: Lean management seeks to establish a pull system, where each step in the process only produces what is needed by the next step. This helps to eliminate excess inventory and reduces waste.

5. Perfection: Lean management is a continuous process of improvement, with the goal of achieving perfection. This involves constantly looking for ways to improve processes and eliminate waste.

6. Respect for People: Lean management recognizes that people are the key to success. It emphasizes the need to respect and empower employees, and to create a culture of continuous learning and improvement.

By following these principles, organizations can create a culture of continuous improvement that drives productivity, reduces waste, and creates value for customers. Lean management can be applied to any industry, including healthcare, manufacturing, and service industries.

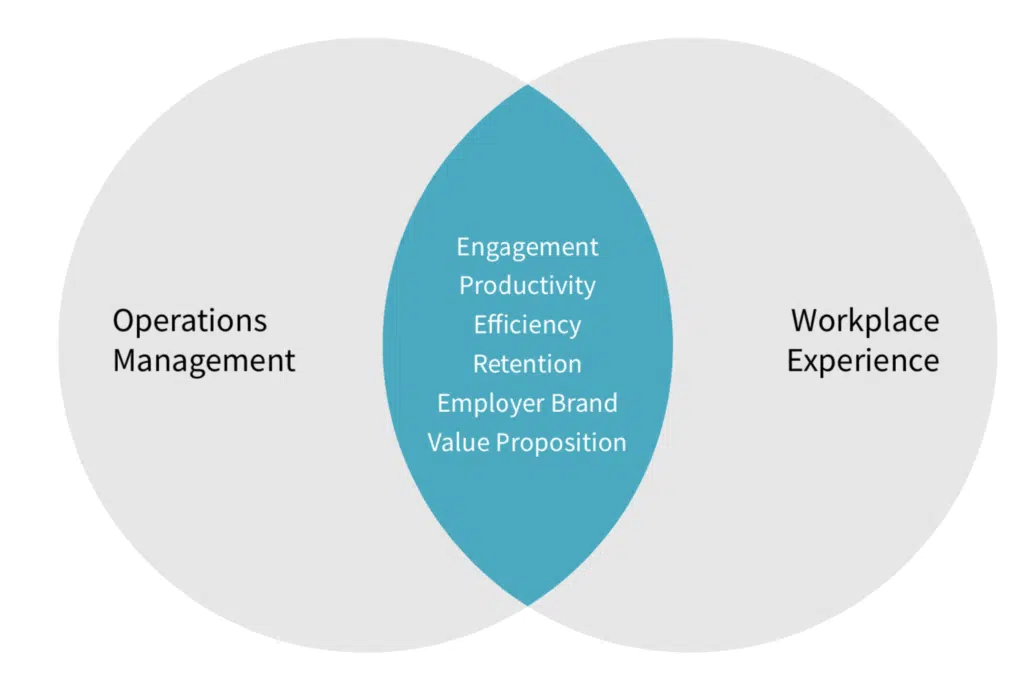

Photo By Beekeeper

Now let’s discuss some lean management practices that can help boost productivity and eliminate waste for healthcare businesses in Africa.

1. Value Stream Mapping

Value Stream Mapping is a lean management technique that involves mapping out the entire process of delivering a product or service. This technique can help healthcare businesses in Africa identify areas of inefficiency and waste in their processes. By identifying these areas, the business can work towards eliminating them, which can lead to increased productivity and efficiency.

2. Kaizen

Kaizen is a Japanese term that means continuous improvement. This philosophy involves making small, incremental improvements to processes over time. By implementing a Kaizen approach, healthcare businesses in Africa can constantly look for ways to improve their processes and eliminate waste. This can lead to increased productivity and efficiency over time.

3. Just-In-Time (JIT) Inventory Management

Just-In-Time (JIT) inventory management is a lean management technique that involves keeping inventory levels as low as possible while still meeting demand. By implementing JIT inventory management, healthcare businesses in Africa can reduce the amount of inventory they need to keep on hand, which can help eliminate waste and increase efficiency.

4. Standardized Work Procedures

Standardized work procedures involve creating standardized processes and procedures for tasks. By standardizing work procedures, healthcare businesses in Africa can reduce the amount of variability in their processes, which can help eliminate waste and increase efficiency.

5. Gemba Walks

Gemba walks involve going to the place where the work is being done and observing the processes in action. By conducting Gemba walks, healthcare businesses in Africa can gain a better understanding of their processes and identify areas of inefficiency and waste. This can help the business work towards eliminating these areas and increasing efficiency.

In conclusion, lean management practices can be useful for healthcare businesses in Africa looking to boost productivity and eliminate waste. By implementing practices such as Value Stream Mapping, Kaizen, JIT inventory management, standardized work procedures, and Gemba walks, healthcare businesses in Africa can identify areas of inefficiency and work towards eliminating waste, which can lead to increased productivity and efficiency over time.

Please leave your comments below.

Leave a comment